Primer on lithium hydroxide (LiOH)

Rechargeable Batteries

Lead-acid batteries feature an electrolyte that actively participates in the electrochemical reactions. During discharge, metallic lead at one electrode loses two electrons and dissolves into the electrolyte solution. When charging occurs, this process reverses—lead ions in the electrolyte gain two electrons and are redeposited as metallic lead on the electrode surface through metallic plating.

In contrast, lithium-ion batteries operate through a different mechanism where the electrolyte functions purely as an ionic conductor, facilitating ion movement between electrodes without directly participating in the electrochemical reactions. These rechargeable batteries store energy by reversibly intercalating Li+ ions into electronically conductive solid materials.

The rechargeability of lithium-ion batteries depends on this reversible intercalation process, where lithium ions shuttle between the cathode (such as LiCoO₂) and anode (typically graphite) without any metallic plating occurring. During discharge, ions migrate toward the cathode, while the charging process reverses this ion flow when voltage inputs of 3.6–4.2V are applied.

| Property | Lithium | Lead |

| Energy Density (Wh/kg) | 250 | 35 |

| Cycle Life | 2000 | 500 |

History

Historical Development

During the 1970s, British chemist M. Stanley Whittingham pioneered the concept of intercalation electrodes, developing cathode materials with layered structures capable of accommodating lithium ions while maintaining crystal stability. This breakthrough led to the first rechargeable lithium-ion battery, though it never reached commercial production. Building upon Whittingham’s foundation, John Goodenough advanced the technology in 1980 by implementing lithium cobalt oxide cathodes, which resolved significant technical limitations present in the original cathode materials.

Initial lithium-ion battery designs incorporated lithium metal anodes, but these were eventually discarded due to serious safety issues. Lithium metal’s inherent instability and tendency to form dendrites created short-circuit risks. The breakthrough came with adopting intercalation anodes that mirrored cathode principles, eliminating lithium metal formation during charging cycles.

Akira Yoshino created the first modern lithium-ion battery prototype in 1985, replacing lithium metal with a carbon-based anode. Sony launched commercial production of the world’s first rechargeable lithium-ion batteries in 1991 using Yoshino’s design. The following year saw Toshiba and Asahi Kasei Co. introduce their own lithium-ion battery through a joint venture.

Energy density improvements marked the 1990s as Yoshino’s soft carbon anodes were successively replaced with hard carbon and eventually graphite materials.

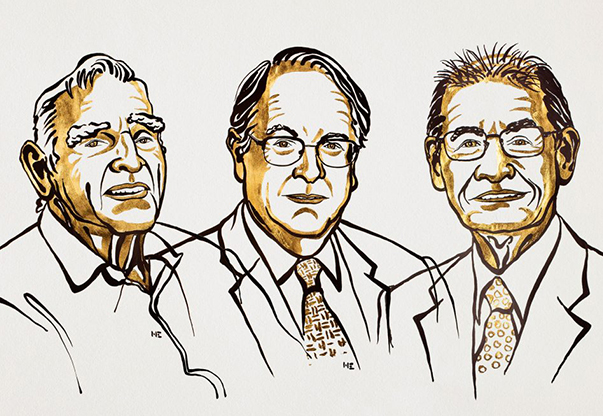

The 2019 Nobel Prize in Chemistry recognized Whittingham, Goodenough and Yoshino for their pivotal contributions to lithium-ion battery development.

Recently, CATL announced in April 2023 plans for scaled production of semi-solid condensed matter batteries achieving 500 Wh/kg through reduced electrode weight. These batteries employ gelled electrode materials that require fewer binding agents.

Stanley Whittingham, John Goodenough & Akira Yoshino

Nobel Prize in Chemistry 2019

Lithium’s Advantages

Lithium-ion batteries consist of four essential components: cathode, anode, electrolyte, and separator, generating electricity through chemical reactions involving lithium ion movement between electrodes.

Lithium’s exceptional electrochemical characteristics make it the preferred battery material. Its lightweight atomic structure (6.94 g/mol) combined with high electron mobility facilitates rapid ion transport between electrodes. The impressive standard electrode potential of -3.04V significantly surpasses alternatives such as lead (-0.13V) or nickel (-0.25V), allowing higher cell voltages with reduced series connections. Additionally, lithium’s compact ionic radius (0.76Å) minimizes structural stress during intercalation, decreasing battery degradation.

Beyond voltage benefits, lithium’s favorable kinetics support rapid charging capabilities. Currently, lithium’s optimal combination of energy characteristics and kinetic properties makes it irreplaceable.

These properties enable the creation of compact, lightweight cells delivering high voltage (3.2–4.2V per cell) and extended cycle life (500–2000 cycles), powering everything from smartphones to electric vehicles. Advanced lithium-ion chemistries such as NMC and LFP provide enhanced stability and safety through optimized cathode designs.

Lithium maintains its market dominance through superior energy-to-weight ratios and voltage consistency. Although alternatives like sodium-ion batteries are gaining acceptance for stationary energy storage, lithium remains essential for mobile applications.

What is lithium hydroxide?

Lithium hydroxide is an essential inorganic compound widely used in the battery industry. Appearing as a white crystalline powder, it is strongly alkaline, highly soluble in water, and slightly soluble in ethanol. These properties make it particularly suitable for high-tech industrial processes, especially in the production of lithium-ion batteries.

The importance of lithium hydroxide in battery manufacturing

Lithium hydroxide plays a central role in producing lithium-ion batteries, particularly for high-nickel ternary cathode materials such as NMC 622 and NMC 811 ( a type of batteries which are composed of nickel, manganese, and cobalt in ratios of 60:20:20 and 80:10:10, respectively). These advanced materials are critical for electric vehicles, thanks to their high energy density and superior performance as compared to rival cathode chemistries

Advantages over lithium carbonate

Lithium carbonate is traditionally more affordable due to simpler processing requirements and abundant supply.

One of lithium hydroxide’s key advantages however is its lower melting point. In its monohydrate form, it melts at around 471°C, compared to 720°C for lithium carbonate. This lower temperature improves the sintering process (a method in which powdered materials are compacted and heated to form a solid mass without melting), allowing for better integration with precursors and reducing the formation of surface lithium residues. As a result, the final cathode material offers higher specific discharge capacity and improved consistency.

Sintering at lower temperatures also helps limit cation mixing, where metal ions shift from their ideal positions, leading to enhanced cycling stability and longer battery life. In contrast, lithium carbonate generally requires sintering at temperatures above 900°C, which can be less efficient and more challenging to control, especially for high-nickel materials.

Applications in ternary cathode materials

Due to these benefits, lithium hydroxide is preferred for high-nickel chemistries such as NMC 622, 811 and NCA (nickel-cobalt-aluminium oxides). These materials demand precise thermal control and deliver superior energy storage performance.

Unlike high-nickel ternary materials, middle and low nickel ternary materials such as NCM 523 and NCM 333 have higher sintering temperatures. To reduce raw material costs, battery-grade lithium carbonate is mainly used as the lithium source. NCM 622 can use either lithium carbonate or lithium hydroxide, but lithium hydroxide can bring about more ideal electrochemical performance, hence being the preferred choice for overseas cathode material manufacturers.

Lithium carbonate is also used, in alternative chemistries such as Lithium Iron Phosphate (LFP, LiFePO₄) and Lithium Manganese Iron Phosphate (LMFP, LiMnₓFe₍₁₋ₓ₎PO₄). LFP-based chemistries have gained traction due to their lower cost, improved cycle life, and lower ignition risks, making them a compelling choice for applications where ultra-high energy density is not critical.

Lithium hydroxide is more than just a raw material, it is a strategic enabler for next-generation battery technologies. Its thermal and structural advantages make it the preferred lithium source for high-performance applications, positioning it as a cornerstone of the energy transition and the future of e-mobility.

At Viridian Lithium, we are building the first independent European lithium refinery dedicated to converting lithium carbonate into battery-grade lithium hydroxide monohydrate (BG LHM). By doing so, we aim to strengthen the strategic autonomy of the European battery value chain, produce a reliable and sustainable supply of battery-grade lithium chemicals, and contribute to the continent’s industrial sovereignty in the face of growing global demand.

Want to know more about lithium chemicals production?